Essential Gear

Impact Comfort Foam Customizable Protection Sheets

GF-Enhanced Integrated Knee Pads

SmartFlex® Sheets Customizable Impact Protection (pack of 5)

GF-Enhanced Integrated Elbow Pads

GF KO Internal Knee Guards

ECH Helmet Suspension System (9-Pad)

ECH Helmet Suspension System (7-Pad)

impact areas covered

Protection for All

Battlefield

From training to combat operations, your gear must prioritize survivability. At G-Form, we enhance protection without compromising comfort. Our expanding product portfolio is engineered to deliver impact mitigation across all extremities, the torso, head-worn systems, and load carriage.

Law Enforcement

Every day, you suit up to face unpredictable environments in full view of the public. G Form applies advanced protection technologies developed for athletes and the military to meet the unique demands of law enforcement. Our gear is built for all-day wear—durable, lightweight, and designed for 10-hour shifts.

Codes & Definitions

Our testing standards vary by the area of protection. Limb Protection = EN1621-1 Level 1; Hard Armor = Ballistic Back Face Deformation; Head Protection = Maximum G-force Acceleration Thresholds. G-Form products undergo rigorous independent in-house or third-party testing.

Fit & Sizing Guide

Accurate sizing is critical for comfort and performance. Refer to our detailed fit and sizing charts to find the right gear for your needs. See Guide.

Partnerships

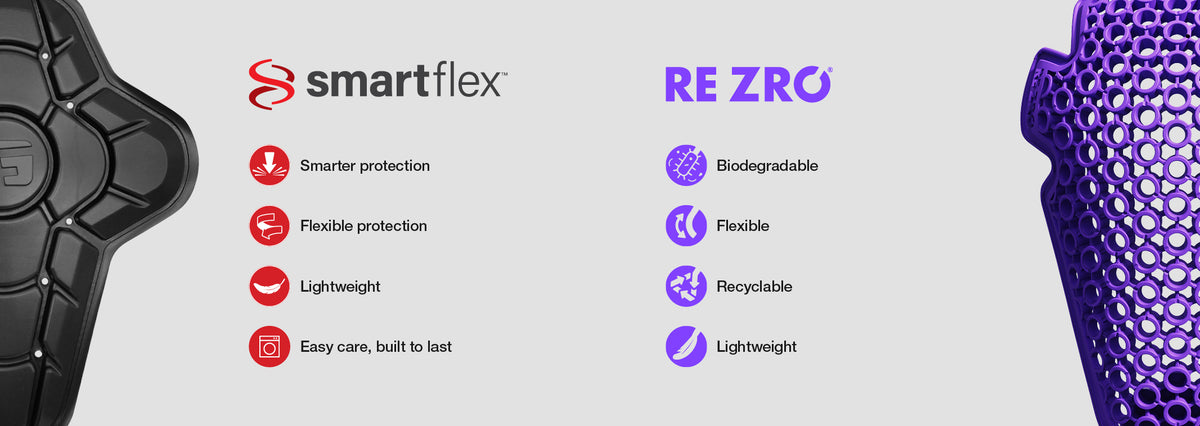

The new standard in protection